marLiN2

marLiN2 Refill System

marLiN2 - Controller front panel

marLiN2 - Controller back panel

Supply dewar and dewar for cryo-cooler operation

Fittings on dewar for cryo-cooler operation

Cryo-cooler dewar fitting

Refill dewar valves

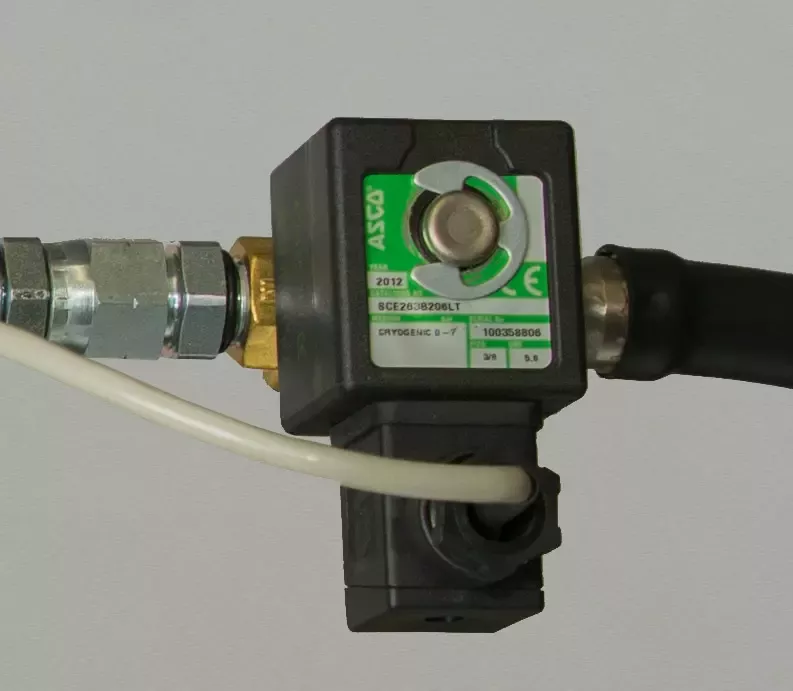

Magnetic valve

Weighing scale

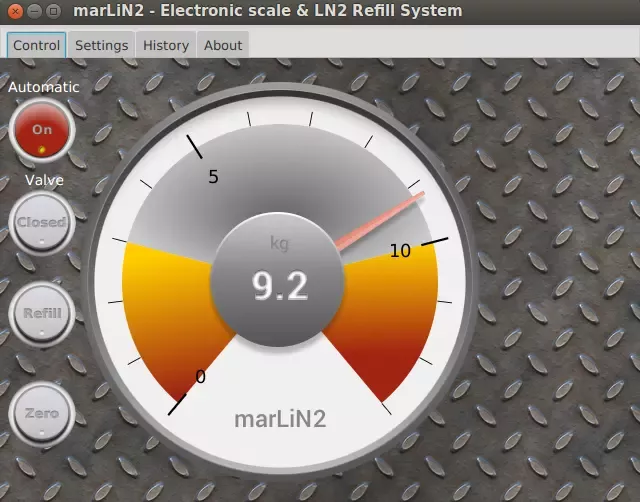

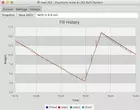

Desktop app

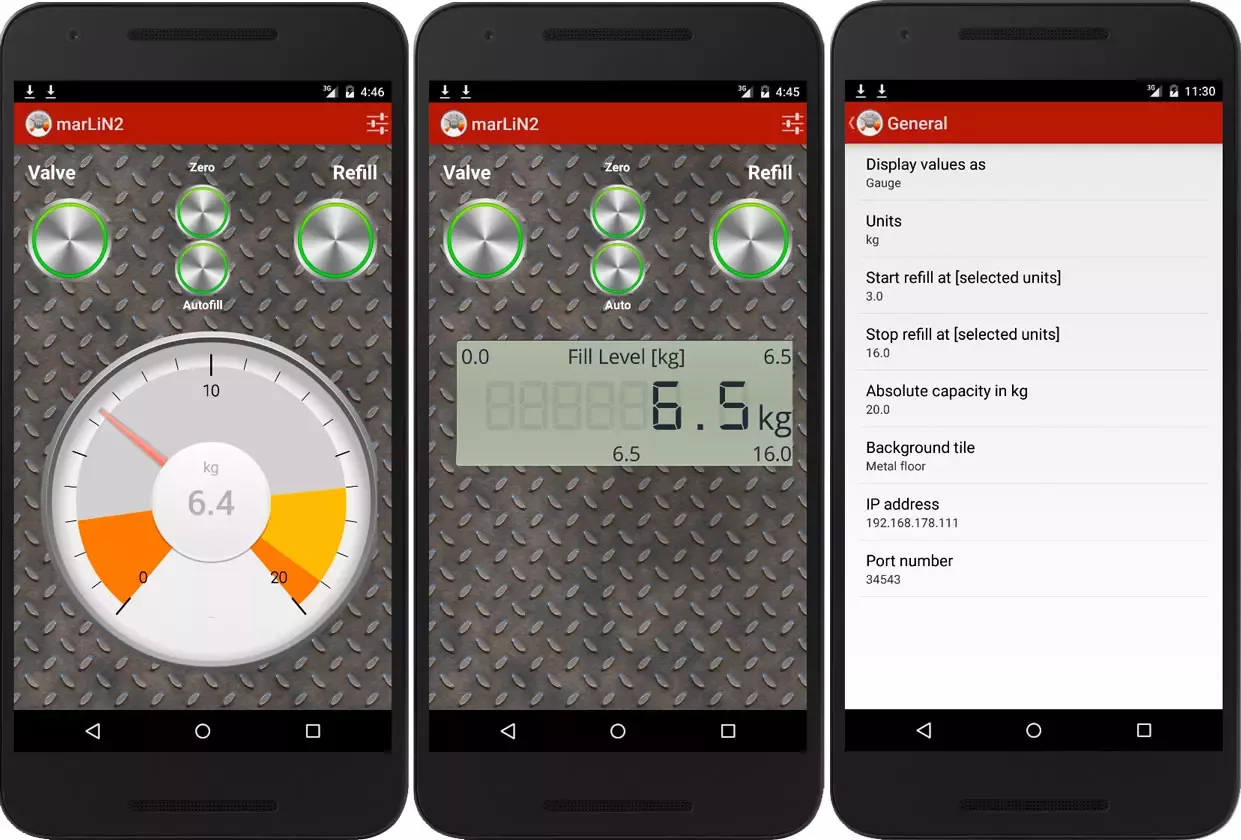

Mobile app

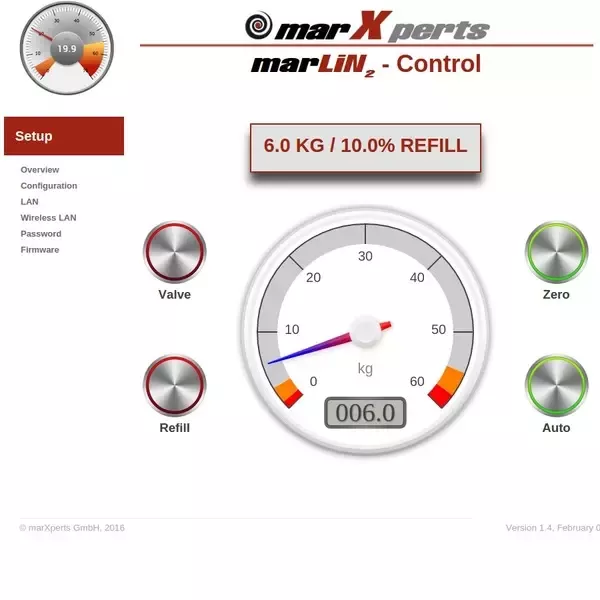

Web interface

The marLiN2 is a fully automatic LN2 (liquid nitrogen) refill system. It is based on a high precision electronic weighing scale, a magnetic valve and an intelligent and versatile controller that automatically tops up an unpressurized LN2 dewar (typically 60 liters) from a supply line, e.g. a pressurized large LN2 dewar of 150l content or more. The marLiN2 system is the perfect addition to an Oxford Cryosystems Cooler (600, 700, 800 series) or similar systems and can be retrofitted easily to existing systems.

Other than competing products the marLiN2 system makes use of a scale and reliably refills a dewar for long periods of time. Since the heart of the instrument is a general purpose weighing scale, the marLiN2 system can generally be used for any application with th requirement to trigger some action at given weight thresholds and can easily be tailored to deal with other applications than cryogenic work.

The marLiN2 system features a state-of-the-art controller with full network connectivity and easy access from Windows, Mac OS X and Linux desktop as well as from mobile devices, either via native apps or via a web browser interface. The controller allows for defining fill levels and send emails or push notifications as soon as the corresponding level is reached.

HIGHLIGHTS

INTELLIGENT CONTROLLER

NETWORK CONNECTIVITY

MOBILE APP

AFFORDABILITY

COMPONENTS

The marLiN2 refill system consists of individual components that may be purchased as a whole package or just as single items. If you already have suitable dewars or a compatible solenoid valve, they can be reused.

SPECIFICATIONS

| Dimensions | 610 mm x 500 mm x 160 mm (l/w/h) |

| Space between scale and ground | 12 mm |

| Max. tonnage of dewar | 150 kg |

| Max. diameter of dewar | 465 mm |

| Input power | 230 V or 110 V AC |

| Output power for solenoid | 24 V AC / 2 A max. current |

| Measurement range | 0:150 kg |

| Display accuracy | 0.1 kg |

| Display units | kg or liter, percent and time of refill |

| Display type | 16-character x 2-line backlit LCD |

| Alarms | Buzzer, LED, push-message to cell phone |

| Temperature range | 0-40 C |

| Dimensions | 240 mm x 200 mm x 85 mm (l/w/h) |

| Connectivity | RJ-45 fast Ethernet Optional WiFi-dongle (USB) |

| Connections | NTC 3/8" female thread, 12 mm fitting |

| Type of valve | ASCO SCE 263B206LT 24V AC |

| Isolated tube | 3 m metal wafe tube with insert Teflon tube, 3/8" male/female connections |

SOFTWARE

The user interface for the device is as simple as can be since the typical usage is a stand-alone operation for long periods of time. The instrument with reasonable presets for minimum and maximum fill levels that can easily be modified by software - no fiddling around with cryptic buttons and hard-to-read manuals.For ease of use, a full range of software is provided. Configuration and monitoring is most easily done from a web interface on any platform without having to install software. Mobile apps for Android and iOS are available from Google's Play Store and Apple's App Store, respectively. For more dedicated use with additional benefits, native executables are available for Windows, Mac OS X and Linux desktops. Desktop apps are compiled using Java 8u91 and may require a recent Java runtime environment.

| Web |  |

|

|

|

| Desktop |  |

|

|

|

|

Android |

|

|

|

|

|

iOS |

|

|

||

Software for desktop PC's:

| Operating System | Compiled on | Architecture | Action |

|---|---|---|---|

| Windows | Windows 10 | 64-bit | |

| Windows 7 | 32-bit | ||

| Linux (deb) | Ubuntu 16.04 | 64-bit | |

| Ubuntu 14.04 | 32-bit | ||

| Linux (rpm) | CentOS 7.2 | 64-bit | |

| CentOS 6.8 | 32-bit | ||

| Mac OS X (dmg) | Sierra | 64-bit |

DOWNLOADS

- Product brochure (pdf)

- Product flyer (pdf)

- User manual (pdf)

- Demonstration video for iOS app (mp4, 18MB)